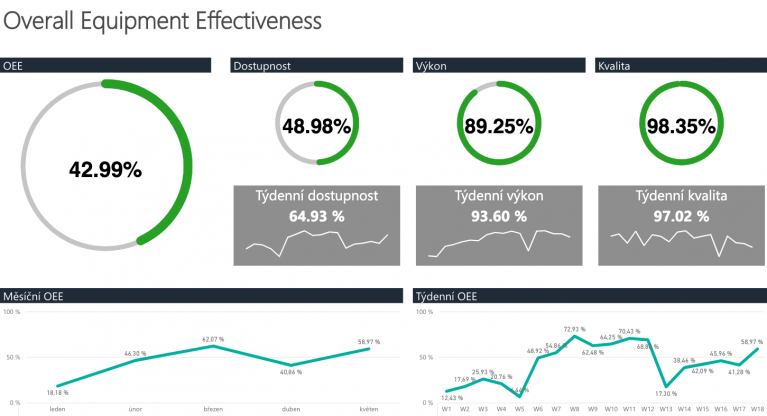

Overall Equipment Effectiveness

We like to say that OEE is the most important number ever, and it’s the number that’s created right before your eyes each and every day in production. Collecting data, and then measuring OEE, can reliably reveal the causes of inefficiency. How efficient is your production?

- With PLANTYST, you can find out what and how much you’ve produced over time

- Uncover hidden capacities in your production facilities

- Learn when and why your production is inefficient In addition, how can you prevent the production of NOT OK pieces.

Why you should care about OEE

Is you production profitable or does it need to be improved on multiple fronts?

No manufacturing statistics can tell you much about your production. With OEE, you track:

- Actual production

- Amount, length and type of planned downtime

- Actual production quantities

- Production flow rates

- Quantity and type of NOT OKs

- Number, length and causes of unplanned downtime

Can a single number really tell you all of this? Yes, it really can. You “just” need to measure and evaluate OEE correctly.

What does OEE affect?

Everything.

Everything in production matters. With OEE, you can find ways to improve on all fronts.

- Costs – how can you ensure the production cost per unit?

- Inventory – you won’t see shortages or surpluses with OEE. You will learn to plan better.

- Material consumption – every NOK costs you extra raw material. Less will now be used.

- Energy consumption – downtime and poor quality production costs you extra energy.

With OEE, you make better use of:

- Space

- Technology

- And most importantly, your own people

On top of everything we’ve already presented, OEE is a reliable indicator of where human labor is being wasted.

Why is OEE so important for you?

It will be a reliably identify the causes of production inefficiencies.

It accurately expresses the ratio of production efficiency to inefficiency.

When you get OEE right, every single employee contributes to its improvement.

Availability

Do you want a better OEE? You need to look for the causes of downtime. How much of your working time do you actually produce?

Performance

Focus on measuring the output of products you produce most often and in the largest quantities. These are the values you should be interested in improving.

Quality

The more difficult it is to measure quality correctly, the more important it is to measure it. How can you produce quality? It’s pretty simple. Don’t produce poor quality.

Unlock the full potential of your production processes

Extend the service life of your machines. Expand production capacity. Increase production efficiency. Reduce production costs.

PLANTYST is the key.